Our Process and the birth of a reclaimed wood table

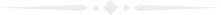

Our reclaimed wood tables begin as beams and joists salvaged from barns, warehouses, and other buildings throughout the east coast. These structures are carefully disassembled maintain the very best condition of the building materials. Normally sent to landfills, this wood and material is now saved and restored for decades of further use.

Saltwoods is very selective about what wood is used for our tables. Only the best quality beams and joist are hand selected. Our reclaimed wood is made from American ‘old growth’ wood, meaning that it is from forests growing in the 1700s. Thus the wood grain is much denser, stronger, and longer lasting than anything from your local lumber dealer.

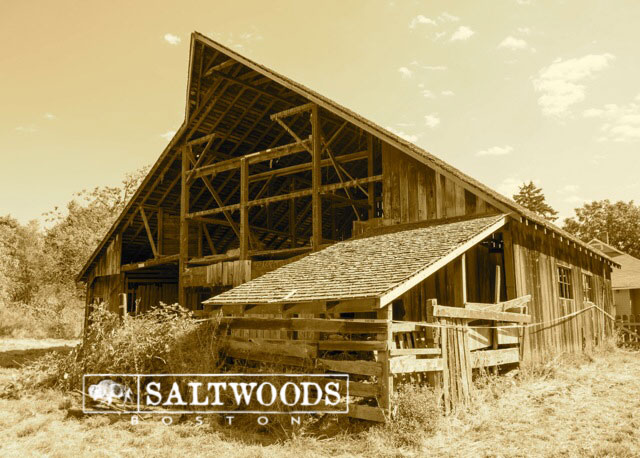

Once the beams have been sorted, they are carefully scanned with metal detectors and denailed on location. Special tools and grips are used to leave the wood as unharmed as possible while taking out the nails; not an easy task with brittle antique iron. After the nails have been removed, the wood is then milled to rough cut boards approximately 2 to 2.5” inches thick. The scraps are sorted out and the solid boards are stacked with sticks between each board to allow for optimum air movement and drying. The carefully stacked boards are then put into the kiln to dry with warm air and create a stable moisture content in the wood. The boards spend about 2 weeks in the kiln with warm air in constant circulation.

Reclaimed Wood beams de-nailed and trimmed.

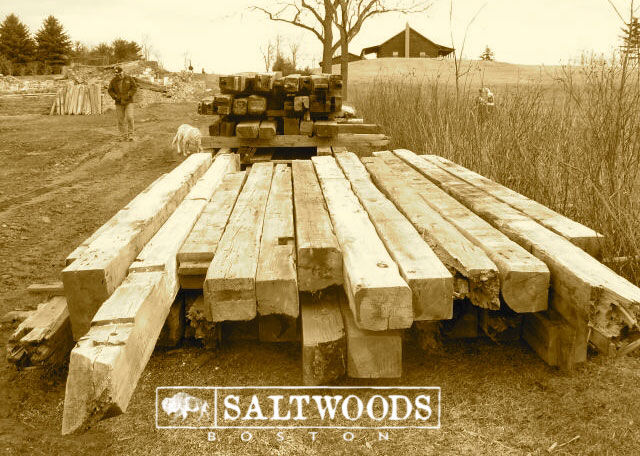

From the kiln, the wood heads into the shop. It is then sent through the ‘joiner’ which gives it two straight flat edges. From here it goes to the planer where the top and bottom surfaces are shaved to give all the boards a standard thickness. Now our wood boards are the approximate thickness we need for a table top. The boards are laid out to give us our first visualization of what we want the top to look like. The most beautiful grains are arranged properly to give us the best looking table.

After measurements are taken, we the put wood glue on the edges are clamp the entire top together. The top will remain clamped up overnight. At this time, legs are also cut to size and glued up.

Reclaimed wood tabletop ready being set

Our skirt wood, or base, is selected and cut to proper size according to the tops dimensions. A rough assembly is made with the top and base/skirt to make proper cuts and adjustments. Once the rough assembly is all set, the table is taken apart for final sanding and finishing.

Base assembly before finishing

Sanding and finishing are the most important; extra time and patience is crucial to a quality build. We have 3 craftsmen per table sanding in three stages; 100 grit, 150 grit, and finally 220 grit. This is where all of the woods beauty truly comes out. And you really see the difference in the finish.

Reclaimed wood table ready for sanding

The final result!