Woodshop Library

How Often?

| For First 2 Months: | Twice/Month |

|---|---|

| For first Year: | Once/Month |

| After First Year: | Once/3-4 Months (or as needed) |

Soft oil finishes on wooden furniture direct from the woodshop need to build up a strong layer of protection over time. Extra care and maintenance early on will set you up for a fantastic piece of furniture for years to come.

Steps:

- Scuff entire surface with fine steel wool (grade #0000) with the grain of the wood.

- Apply a thin coat of oil/wax blend with a lint free cloth*

- After 60 mins. wipe excess oil with clean cloth and buff*

*Avoid spontaneous combustion by soaking oily rags in water and place in a sealed container.

Tips:

If the surface feels sticky:

You may have applied too much oil or too often. Simply scruff surface again (step 1) and rebuff (step 3).

If the surface feels dry:

It may be time to apply another coat of the oil/wax blend.

Everyday maintenance:

Use mild soap and water on a damp cloth to wipe up after meals and daily spills.

Breadboards

What:

Breadboard ends are narrow pieces of wood at each end of the table. They are permanently affixed and within your overall dimensions. Although they are mostly aesthetic, they do add some structure and stability. It should be noted that your table will expand/swell and contract/shrink seasonally and thus the breadboards may stick out slightly, up to .25″ inch (typically in the winter months). Please avoid breadboard ends if this may not appeal to you.

Why:

Wood is a living breathing material and will naturally expand and contract. Breadboards work with the nature of the wood, helping the table remain flat while allowing the wood to shrink and expand without risking cracking or splitting.

Where:

Breadboards can be added for additional support and design to any of our tables.

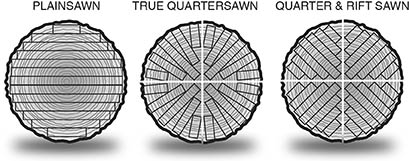

Wood Grain

How the wood is cut determines the grain and the strength and integrity of the final piece.

Types of wood cuts:

Flat-Sawn (plainsawn)

- Features unique cathedral pattern peaks of wood grain.

- Fastest to produce, most affordable, and produces minimal waste.

- Has some structural drawbacks due to tangential grain.

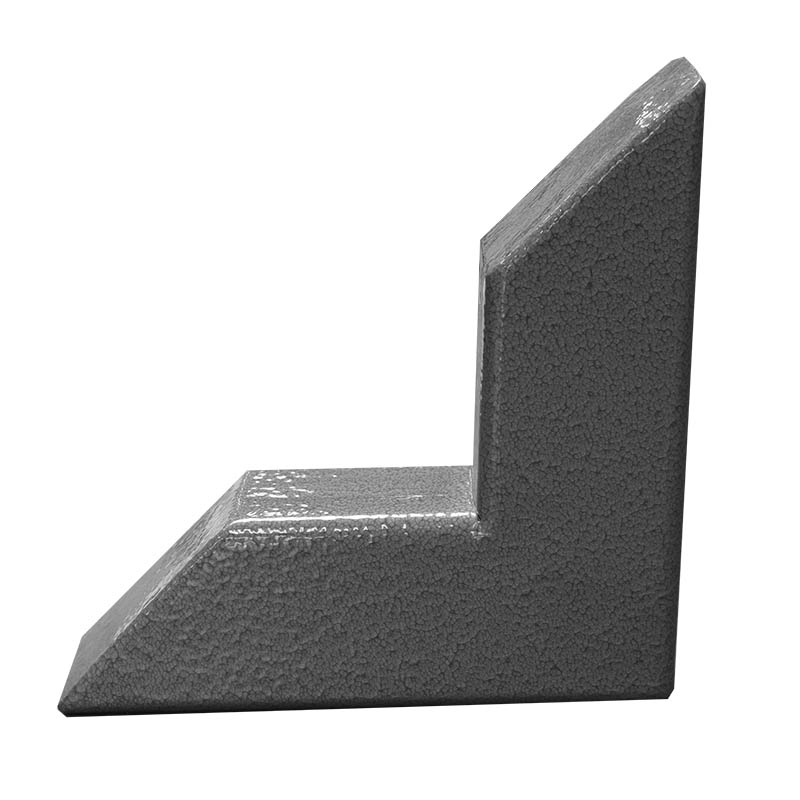

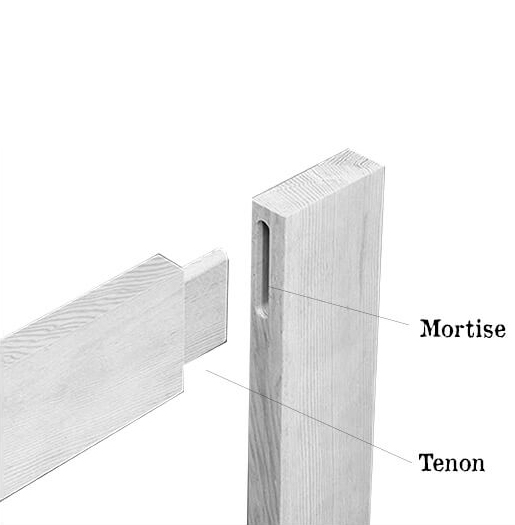

Mortise and Tenon

Superior Strength, Stability, and Style

Similar to the human body, a table will feel most stressors on its joints. A well designed mortise and tenon joint is simple and strong defense against any stressor your table will experience. Such stressors to the table may include getting pushed/kicked around, sat upon, leaned against. To add to this, there is natural movement from the expansion and contraction of the wood. All of this requires a strong leg-to-apron joint design that will hold the integrity of the table.

An Ancient Technique:

- Used by woodworkers dating back over 7,000 years.

- Found in the world’s oldest intact architecture.

Soft Finish (oil/wax) vs Hard Finish (varnish)

Standard Oil

Soft natural finish made from a mix of linseed oil and wax.

Allows the characteristics of the wood to show through while providing a beautiful natural sheen and additional protection against liquids.

Maintenance

Mild soap and water for everyday maintenance. Needs several reapplications of the oil/wax blend in order to build a strong layer of protection.

Varnish

Environmentally friendly water-based hard finish.

Strong against scratches and dings. Standard varnish is low/matte 5 sheen finish. Higher sheen is available on request (40 or 60 sheen), providing a glossier finish.

Stains

Note; all stains are coated with a varnish.

Maintenance

Mild soap and water for everyday maintenance. If you would like to use an off-the-shelf cleaning product, we recommend non-toxic, natural cleaners such as Murphy’s Oil. Varnish does not require reapplication.

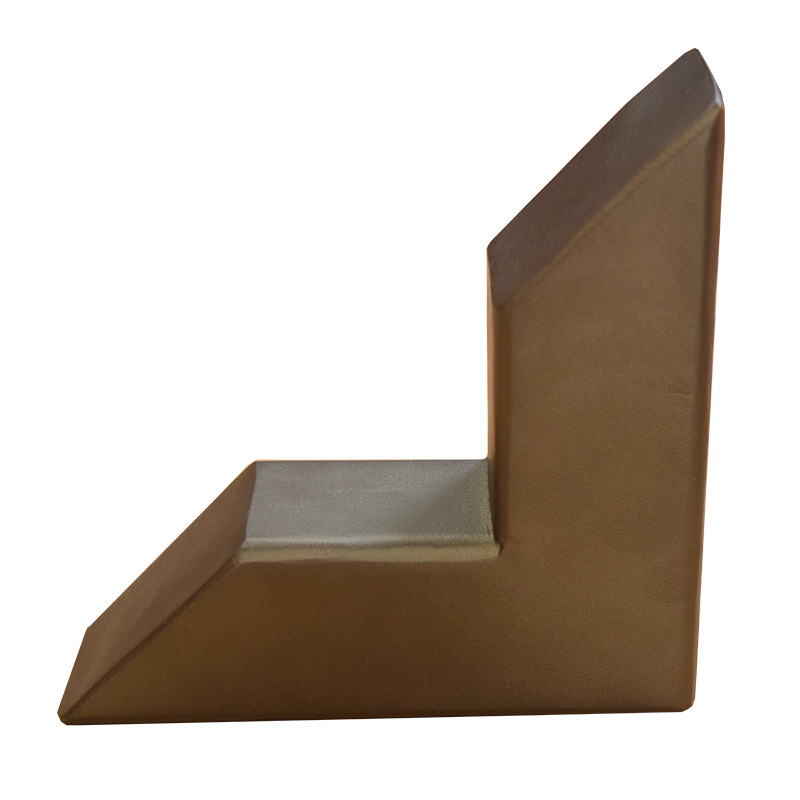

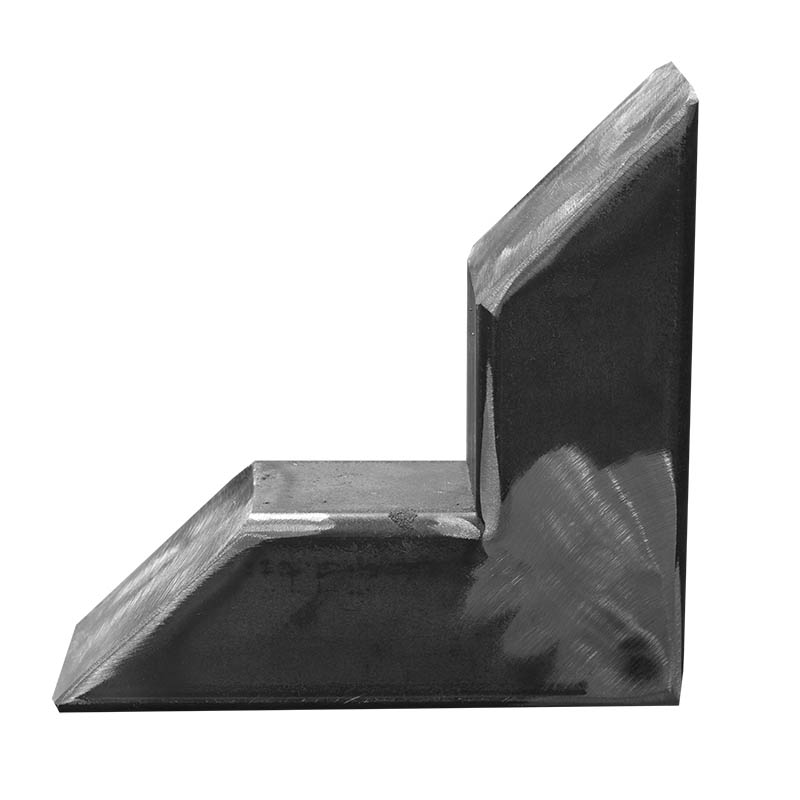

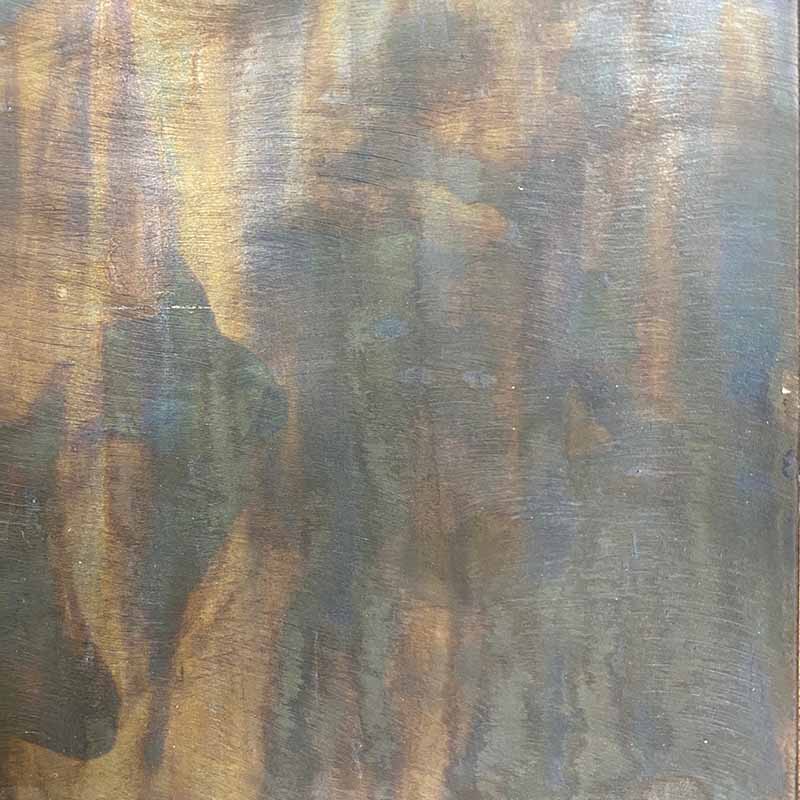

Metal Finishes

Table Shape

*Only straight at the sides

*Straight at the sides, and at the heads

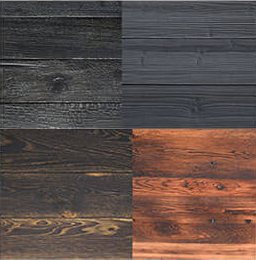

Shou Sugi Ban

Ancient Japanese wood preservation technique

Process

- Wood is torched, cooled, brushes, and finished with either Danish Oil or Varnish.

- Charring process creates a layer of carbon that renders the wood impervious to the elements.

Benefits

- Resilient to rot, decay, fire, and insects.

- Withstands the test of time and can last generations.

- Repels water and requires less maintenance and less oiling.

- Creates a rich in character, unique patina.

Wood Examples

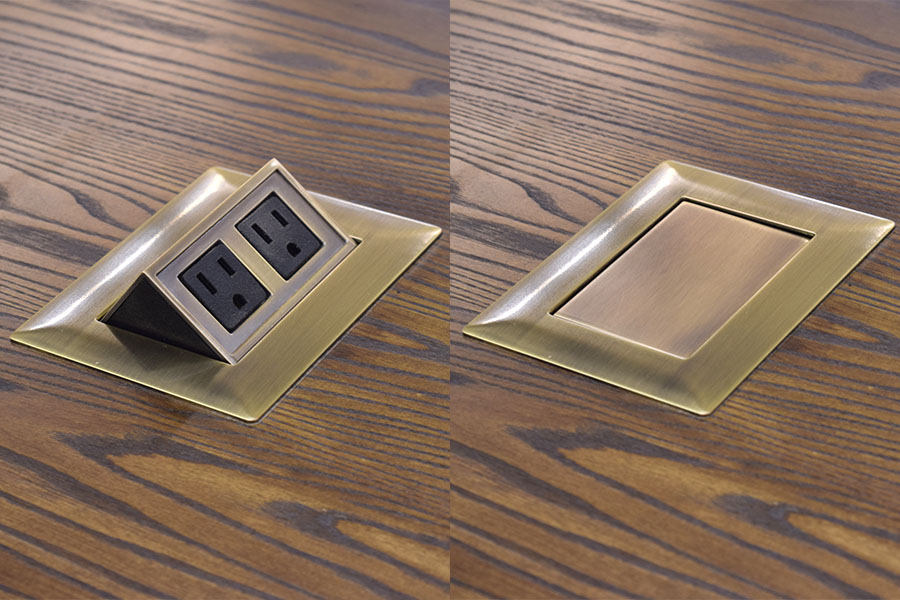

Cable Channel Box

Allow easy access to electrical components and wiring. Keep tour table top organized, clean, and free of clutter.

Additional Info:

Typical size is a 5″ wide top and 6-7″ wide box.

Customizable options include a laser engraved or inlayed logo.

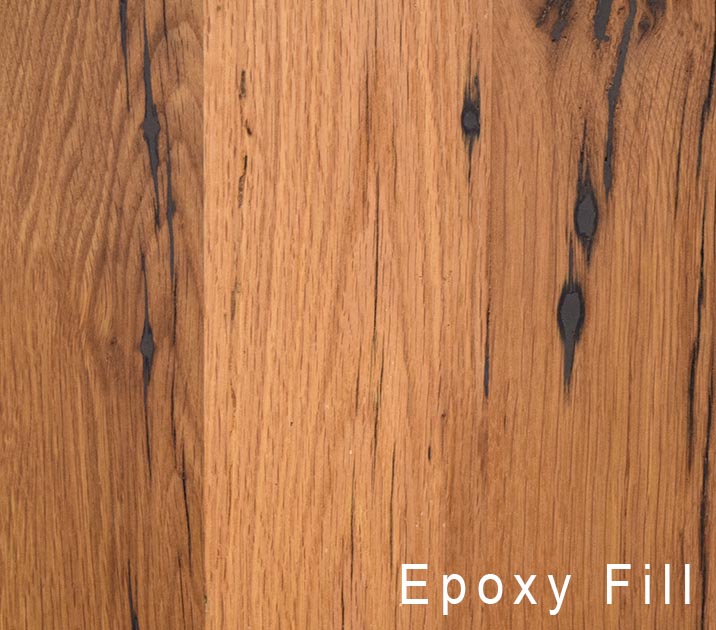

Epoxy Fill Options

Black

Amber

Clear

Epoxy Fill

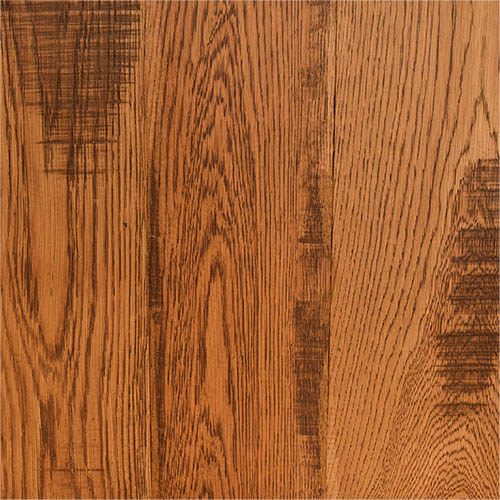

Rough Cut Saw Marks

Various levels of saw marks can be left in for texture, and/or patina. Saw marks can be left in for any type of wood. A great way to leave in a bit of rustic character.

Light Saw Marks

Heavy Saw Marks

*Please note heavy saw marks requires groove between woodboard seams.

Butcher Block vs End Grain

Walnut Butcher Block

Walnut End Grain

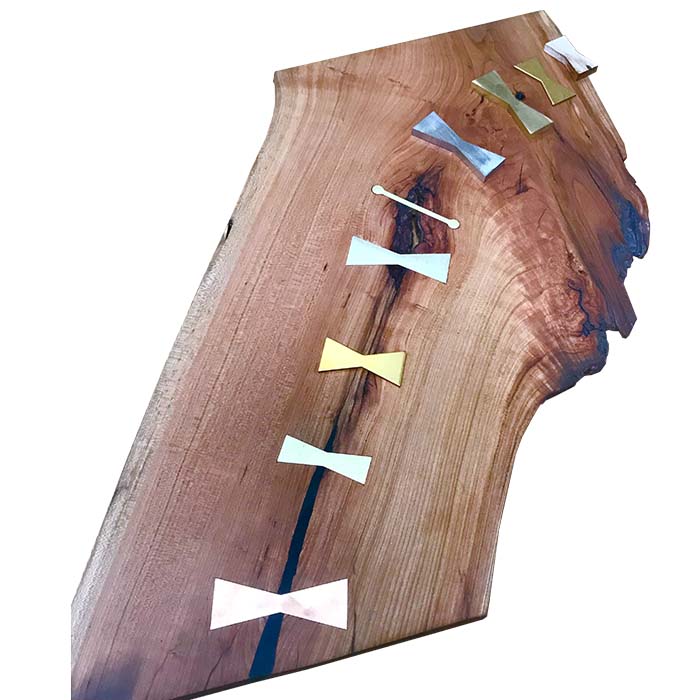

Bow-ties, Butterflies, and Dog Bones

Not only can bow-ties/butterflies, and dog bones prevent cracks from spreading, they are an aesthetically pleasing focal point.

Walnut Bow-ties on Maple

Maple Bow-tie on Walnut

Bronze, Silver, Gold + More